From fire to wheels in history, to everything around us in our present, basically, it won’t be wrong to say that Man is the ultimate inventor of all these things. Inventions are made every day. Some become prominent and others remain unannounced. But among all these, here is a list of some splendid man-made materials that possess the potential to carve the future.

5 Amazing Man-Made Materials that Will Carve the Future

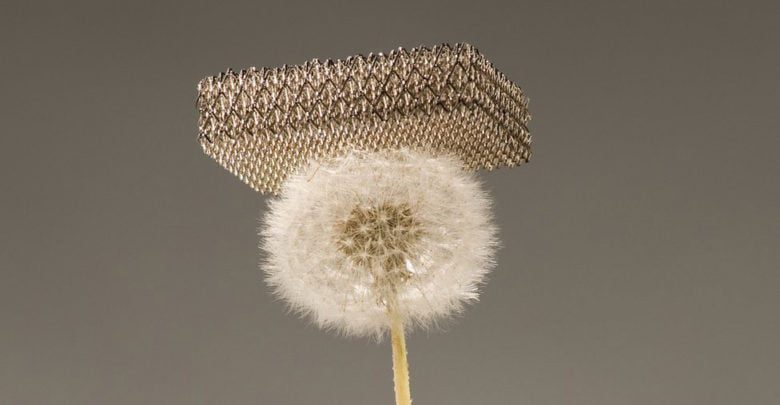

1. Titanium Foam

Titanium foam would make you forget all the traditional expanded polystyrene and spongey elastomers. These titanium foams are created by saturating a humble polyurethane foam with a solution of titanium powder and binding agents. Thus, the metal is propelled to grasp the shape of the simple foam. The underlying structure is then left to vaporize away. Finally, we achieve a titanium lattice in the shape of the original foam. This requires further heat treatment to retain its material properties. The properties of the titanium foam depend entirely on its porosity but no doubt the results are very strong. Especially, this foam is very light and doctors are using it as a replacement for bones. Because it has highly similar mechanical properties. Besides, due to its porous nature, new bones can grow around the formation.

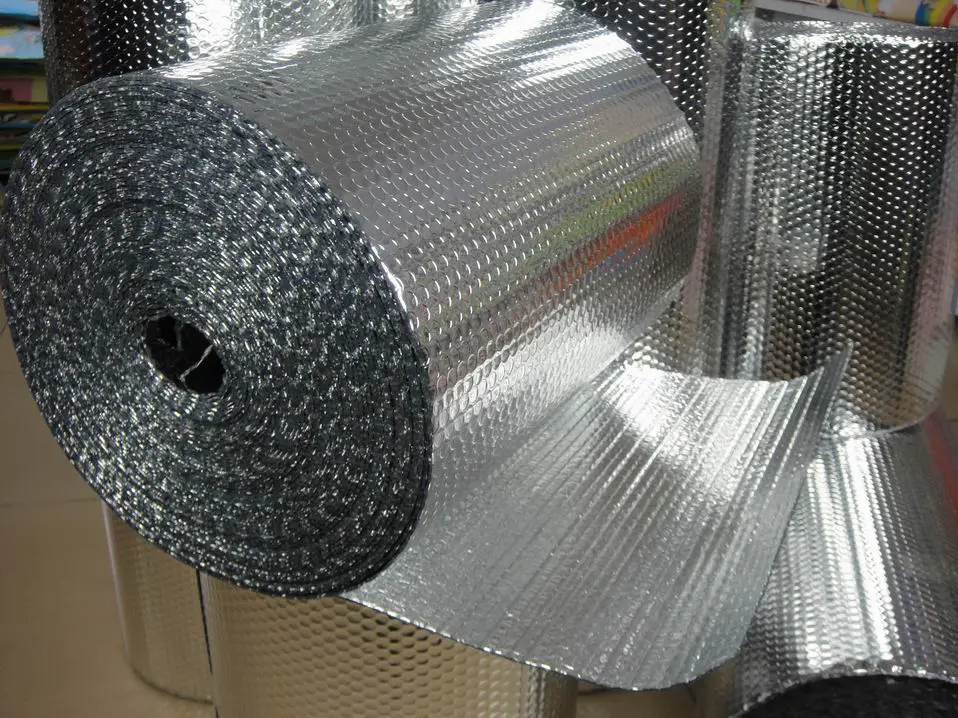

2. Aluminum Bubble Wrap

Bubble wraps are a favorite of everyone because of their bubble pop-up fun thing. But what if we make these bubble wraps using some metal? No doubt it would be quite difficult to pop them up but they would really be a lot more useful then, in comparison to their polyethylene counterpart. North Carolina State University’s engineers have developed a new form of aluminum bubble wrap which is believed to revolutionize the packaging and protective affairs.

The manufacturing process of this wrap includes taking up a thin sheet of aluminum and letting a studded roller form small notches in the sheet. The notches are then filled up with a foamed material like calcium carbonate, before being sealed with another flat sheet of aluminum. So, as a final product, we get an array of bubbles that absorb masses of energy. Besides, this wrap weighs 30 percent lighter than the regular sheet metal but almost 50 times more strengthier. Industries are using these right from the packaging of fragile food items to big bike helmets.

3. Artificial Spider Silk

We are obtaining Silk from natural ways but it has a flaw that we can’t obtain it in bulk. So, one Japanese startup called Spiber attempted to work out on how to produce a similar kind of substance synthetically. They managed to decode the gene responsible for the production of fibroin in spiders. Fibroin is the key protein that is responsible for the creation of super-strong silk strands. So, after cracking this key component, the pace of success rapidly increased. The company created bioengineered bacteria that can make silk exceptionally fast. This led the company to create a new type of silk in just 10 days, right from scratch to the final product. This bacteria was fed on sugar, salt, and other micronutrients. The silk obtained was first converted into fine powder and spun and then further processed to create fibers, composites, and solid blocks or actually anything.

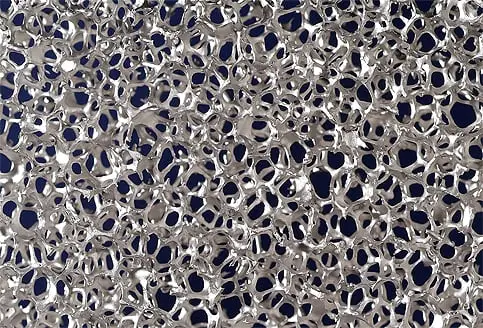

4. Graphene Aerogel

The Graphene Aerogel has recently grabbed the title of the world’s lightest material. This material has a density lower than that of helium and just twice that of hydrogen at 0.16 mg/cm3. This material practically floats. Industries are manufacturing it using a new technique involving a freeze-drying solution of carbon nanotubes and graphene, to form a carbon sponge kind substance. So, the final product is both strong, elastic, and incredibly light. This Graphene Aerogel can absorb up to 900 times its own weight in oil. If this becomes affordable, one can use it to mop up massive oil spills with ease.

5. Molecular Superglue

Must have faced the pain of being stuck due to super glue? A really painful one. Now, you can easily imagine how painful it would be if the glue were to stick at the molecular level. A research team from the University of Oxford has manufactured a molecular glue, inspired by a flesh-eating bacteria, Streptococcus pyogenes. They only examined a single protein from the bacterium, that one which it uses to bind to the human cells. From the same examination, they evolved a molecular glue that forms a covenant bond whenever it aligns with a partner protein. The bonds formed are so strong that when a sample of it was tested, the instrument used to measure the strength broke before it was able to measure.